Picture your design in CAD on your computer screen. You can view, manipulate, and review your data. Now ask yourself how that design would look in front of you in person, at full scale and in-context. What if the product looks completely different in person to what it looks like on the screen?

The HoloLens 2 eliminates all those problems. Developed and manufactured by Microsoft, the HoloLens 2 is a pair of Mixed Reality smartglasses that enable its users to see digital objects in a real-world environment, combining the worlds of virtual and augmented reality.

We recently hosted a webinar, demonstrating some of the best ways you can bring value to your design and engineering processes using the Microsoft HoloLens 2 and our Theorem-XR Experiences, from simply visualizing a single CAD model, to viewing large datasets in multi-user Factory Layout sessions with your colleagues.

Watch the full webinar on Using Theorem-XR and HoloLens 2 for Engineering Reviews.

Key highlights

We picked out 5 key benefits of using the Microsoft HoloLens 2 in Engineering:

1. Visualize your models at full scale.

2. Work collaboratively with other engineers.

3. Make better factory planning decisions.

4. Work with large datasets using Azure Remote Rendering.

5. You can still work with colleagues that are using other XR technologies, or none at all.

1. Visualize your models at full scale

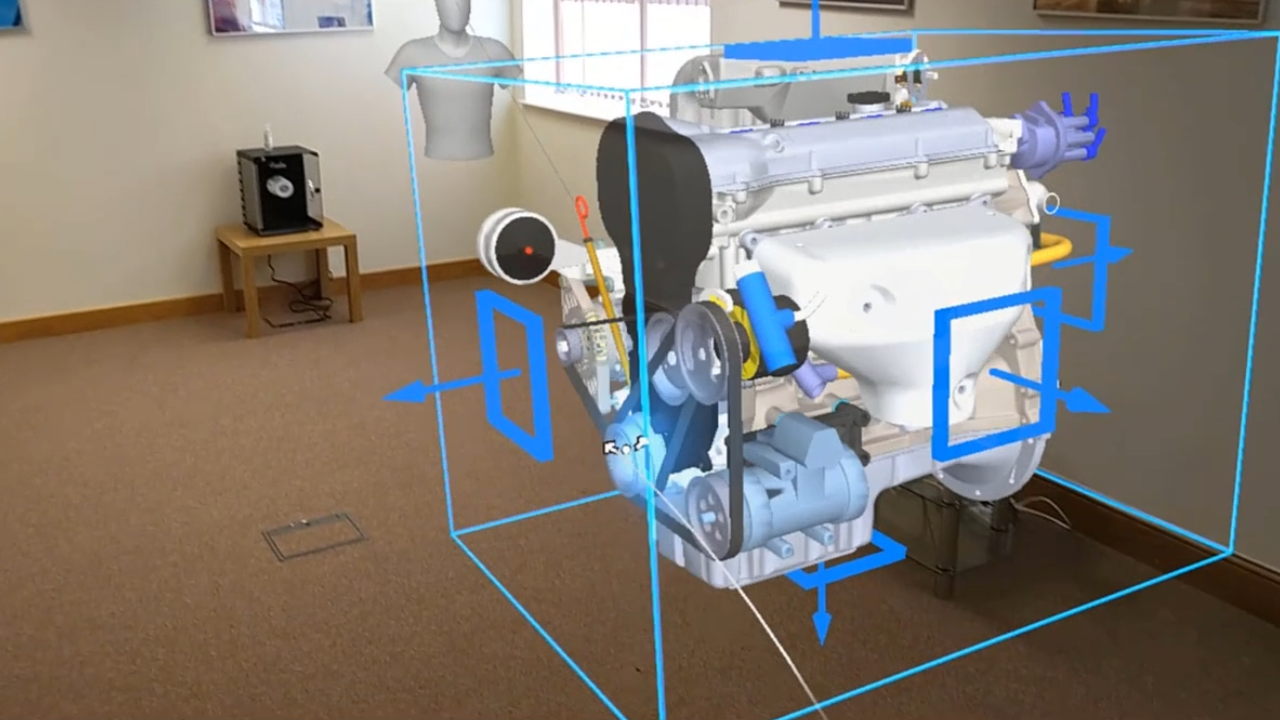

The Visualization experience enables engineers to simply load and interact with geometry, by seeing holographic representations of their CAD data and other digital information. With simple hand gestures, you can grab, move, scale, and freely rotate your models to manipulate and review your data, at full scale.

You can take advantage of numerous features, such as being able to explode assemblies that consist of individual parts. Using the ‘explode’ feature, you can temporarily separate a model into its constituent parts for the assembly, enabling you to review individual parts closer up in person.

“It gives you an idea of controlling the geometry that’s in front of you”

2. Work collaboratively with other engineers in XR

Visualizing design data doesn’t have to be a one-man job, and that’s why Theorem-XR enables users to host multi-user sessions. This means that engineers can review their design and engineering data collaboratively with colleagues, regardless of their location – whether that be another country, office, or even from the living room.

“Here’s one colleague who is on a different device, so he’s sat at a desktop joining this session. And you can see also in the room I’ve got another colleague, and you can see his avatar locked to his head”

Being able to collaborate in real-time using XR technology enables engineers to quickly identify problems with their scenarios, and what might need changing in order to make better and more improved designs. Users can record additional information with a few air taps and hand gestures, which can be saved against collaborative sessions for later review.

"We can also add comments, we can record pictures, video, audio, and associate it to the model itself”

3. Make better factory planning decisions

Using a HoloLens 2, you can load multiple digital models to represent machinery, bring in other pieces of geometry, and lay them out to make better decisions and speed up factory planning. Some practical examples of how manufacturers can use HoloLens 2 for factory planning include...

• Moving individual components and snapping the geometry to the floor, to see how models look in full context.

• Working in multi-user sessions with other engineers to improve communication and make collaborative decisions.

• Using built in motion replay data, to identify the movement and paths of robots and other machinery in a real-life environment.

• Adding new components to layouts and using measuring tools with hand gestures, to ensure logical positioning and avoid any clashes.

By using the Factory Layout experience in HoloLens 2, users can make better and more informed decisions using digital geometry in the real-world environment, reducing the cost and time spent of having to re-design layouts in person whenever new decisions are made.

Learn how Valiant TMS adopt Theorem-XR for their Merged Reality Concept.

4. Work with large datasets using Azure Remote Rendering

At first, working with huge amounts of data may seem unrealistic, with the fear of exceeding the local capacity of your HoloLens 2 device. In this case, the Azure Remote Rendering comes into action. As Microsoft Mixed Reality partners, Theorem’s Visualization Pipeline and XR experiences seamlessly integrate with the Azure platform, enabling manufacturers to livestream their data in the cloud, to work with large volumes of data.

“If you have so much data – you have millions of polygons and gigabytes of source data that exceeds the capabilities to process on the device itself, you can process all that geometry in the Azure Remote Rendering space”

With all your CAD data and geometry being rendered in the cloud, you can still visualize all your data using your HoloLens 2, whilst achieving high frame rates to ensure a high-quality experience of your CAD data, in real-time with your colleagues.

Read about Theorem’s partnership with the Microsoft Mixed Reality programme.

5. Device choice doesn’t prevent collaboration

One thing that often holds some people back from committing to the HoloLens 2, is that other people in their network may be using other technologies. Because of the nature of the Visualization Pipeline, users can actually mix and match devices to best suit requirements within that session.

“You may have a scenario where you have HoloLens 1, HoloLens 2, VR headsets, and also people without any immersive technology using a simple desktop. They can all be in the same session at the same time"

Summary

Mixed Reality is the future that we’ve all been dreaming of and the HoloLens 2 is quickly becoming one of the most useful tools in manufacturing, as companies from around the world look to adopt these technologies as part of their digital transformation strategies.

Learn more about using Theorem-XR to enhance your design and engineering processes with Mixed Reality, or contact us directly for more information.