Enter 3D PDF technology – a game changer in the creation and sharing of technical documents, enhancing both internal and external communication.

The journey of bringing a product from concept to production involves navigating through multiple stages, processes, and departments before it’s ready for manufacture and sale. Throughout this journey, particularly during the design phase, a vast amount of information must be meticulously documented and communicated across the organization to ensure the product remains both cost-effective and viable. This data exchange, whether internal, external, or across the supply chain, happens using many different types of documents and formats.

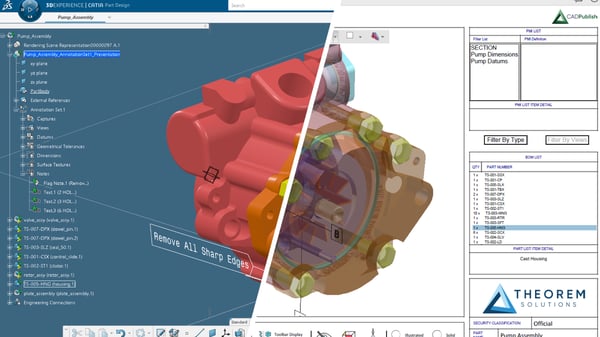

Engineering and manufacturing companies have long relied on CAD systems like CATIA, NX, and Creo to streamline product development. These tools have allowed companies to create, validate, analyze, and document product designs with greater speed and accuracy. However, much of the crucial technical data generated within these systems is confined to specialized CAD and visualization software, such as JT, Creo View, and STEP, which is often only accessible to those trained to use it. This creates a barrier for other stakeholders who need to interact with this data.

What is 3D PDF?

A 3D PDF is a standard PDF document embedded with interactive 3D content derived directly from design data, making it accessible to anyone who needs it.

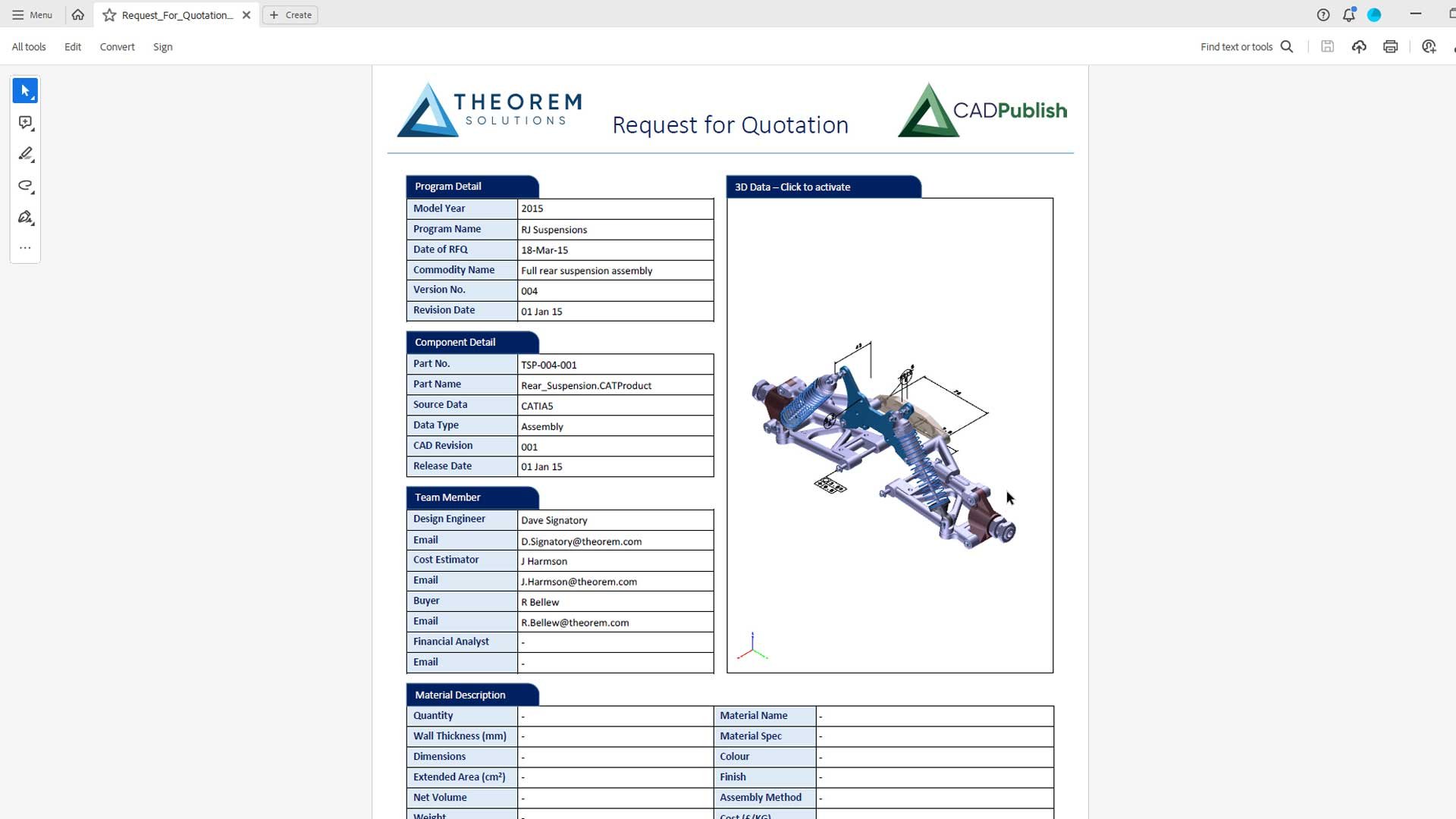

So, how does a 3D PDF revolutionize the way we share and communicate data within organizations and across supply chains? The 3D PDF format allows rich 3D CAD data to be embedded within a document that can be viewed, manipulated, and marked up using Adobe’s free PDF reader. This broad accessibility means anyone with Adobe Reader can not only view the 3D content but also incorporate it into their own documentation processes, eliminating any ambiguity when reviewing product data.

This expanded access to CAD data means it can be more effectively utilized across various departments:

- Engineers can more easily collaborate on new designs, both internally and with suppliers.

- Marketing teams can use CAD models to develop more compelling promotional materials.

- Purchasing teams can enhance Request for Quotation documents with 3D content.

- Shop floor workers can benefit from work instructions that include interactive 3D models.

Templates can make 3D PDF even more flexible, enabling custom documentation to be created for a wide range of uses. This can include company branded technical data package documents, bill of materials, data exchange notices, work instructions, request for quotation, and more. Since these documents can be tailored to fit specific use cases, users can ensure that all the information needed is presented in a way that in understandable and easily accessible.

Why Use 3D PDF?

3D PDFs support Model-Based Definition (MBD) practices, transforming the design and manufacturing process into a fully digital, paperless workflow. By adopting an MBD approach, all necessary product information is captured within a single annotated 3D CAD model, which can then be shared via a 3D PDF, making it accessible to anyone involved in the manufacturing process.

Additionally, 3D PDFs provide enhanced protection of Intellectual Property (IP) compared to native CAD files, offering password protection to prevent unauthorized access. Unlike native CAD files, which cannot be password-protected, 3D PDFs safeguard sensitive information by preventing the native CAD data from being accessed or extracted from the PDF.

As an ISO standard and a lightweight format, 3D PDF is well-suited for a wide range of documentation needs. It can be generated from various CAD systems like CATIA, NX, and Creo, as well as other 3D formats such as JT. Its lightweight nature ensures that 3D PDFs are ideal for collaboration while maintaining the fidelity of the original 3D geometry and product data.

In Summary

With 3D PDFs being easily accessible via Adobe Reader, organizations now have a powerful tool to share information across departments and throughout supply and distribution chains. The simplicity, low cost, and ease of use of 3D PDFs enable seamless integration of stakeholders into the product lifecycle, ultimately leading to shorter lead times, fewer errors, and higher-quality products.

To explore how 3D PDF can enhance your organization’s processes, contact our team today.