In today’s engineering and manufacturing environment, products are rarely made by a single manufacturer. Companies need to collaborate, and often that means sharing design data.

In this article, we’ll be talking about how to help resolve the issues that come with working with partners and suppliers who design using different CAD applications. This can cause incompatibility issues and project delays when sending or receiving data to customers and suppliers.

Using the Source CAD

You could buy seats of the source CAD system to access any incompatible data you receive, but this can add significant expense to a project. Training users on a new system can also be costly and time-consuming. As a result, it’s not always the most efficient or cost-effective option, especially for smaller companies. Even after investing in new CAD software, the data may still need to be accessed in an alternative form further down the supply chain.

Neutral Formats

One common method of sharing design data is to use a neutral file format like STEP. These formats can make data sharing easier, particularly in a supply chain that uses many different CAD systems. By using a standardized format, you can make data accessible to many CAD users, as the files can be read by their software. However, there is a risk of data loss when working with a neutral format, which can result in reduced accuracy.

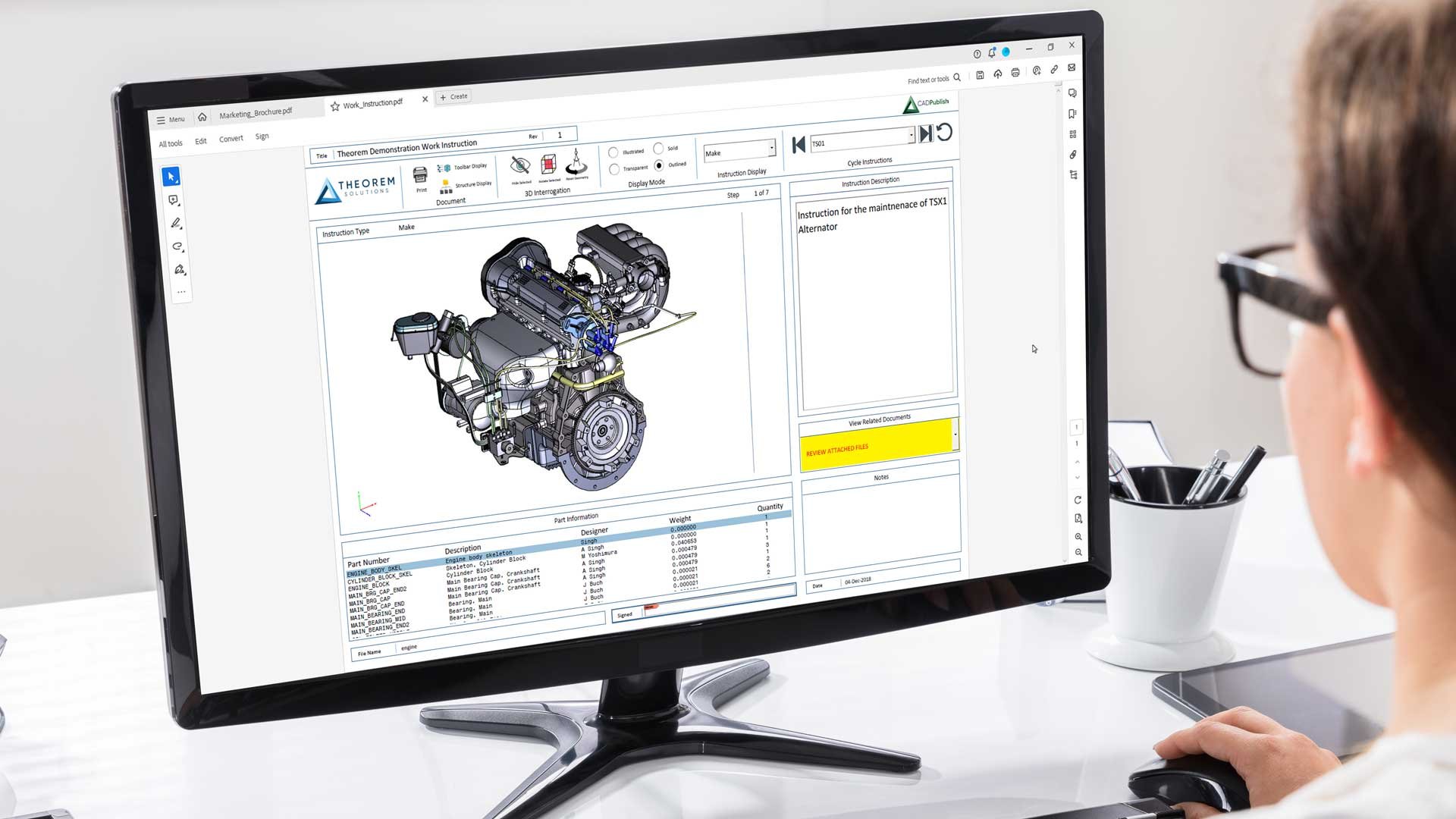

3D PDF

Alternatively, if you are collaborating with partners and suppliers who only need to view design data, 3D PDF may be the best solution. Instead of sharing native CAD or a lightweight visualization file (e.g. 3DXML, Creo View, or JT), you can send a PDF that contains an interactive representation of your CAD model. This has the added benefit of protecting your IP, since you aren’t sharing the native file. Plus, PDFs are easy to share and accessible to anyone with Adobe Acrobat Reader – making collaboration even simpler. You can also use templates to tailor additional information alongside your CAD model and attach other documents to the PDF to provide extra context.

CAD Translation

Another option for solving the issue of collaborating with design data is being able to translate your 3D CAD data from one system to the other. With a direct data translator, you can simplify sharing data between users of incompatible data formats. This can be a more cost-effective method of exchanging data between CAD or visualization systems, allowing you to collaborate with partners and suppliers effectively.

When using a CAD translator, there are a few points to think about in relation to the sending and receiving of data to make sure the translation is as seamless as possible.

When sending data

- Send only high-quality data.

- Know what your data will be used for and only send lightweight data if possible.

- Translate only what the recipient needs.

- Think about whether features and history are required.

When receiving data

- Know what you’re expecting to receive and check when you get it.

- Understand what you have received.

- Double check the sender before opening files.

- Store incoming data securely.

There is no one-size-fits-all solution for data exchange, it’s important to think about the type of data and its content. Whether it’s for manufacturing, viewing only, or if it needs simplifying to protect intellectual property – different data exchange solutions can fit different purposes.

How We Can Help

Accuracy will always be important when working with design data, and you have to be sure your translator’s output is correct. We are partnered with all of the major CAD vendors, and our robust translators are built using their APIs, which ensures an accurate translation because they are not reverse engineered. We offer easy translation for CAD to CAD or between CAD and visualization formats, allowing us to support a wide range of companies based on their collaboration needs. We also offer options for creating 3D PDFs, including customizable and branded templates.

For more information about our CAD translation and 3D PDF solutions, check out our CADTranslate and CADPublish pages. You can also follow Theorem on LinkedIn for the latest news and tips on CAD data exchange.