One of the most ironic aspects of the manufacturing industry is that organisations are constantly talking about digital transformation – building a smart factory, autonomous systems, machines etc., but are still using 2D printed drawings for product design and manufacturing.

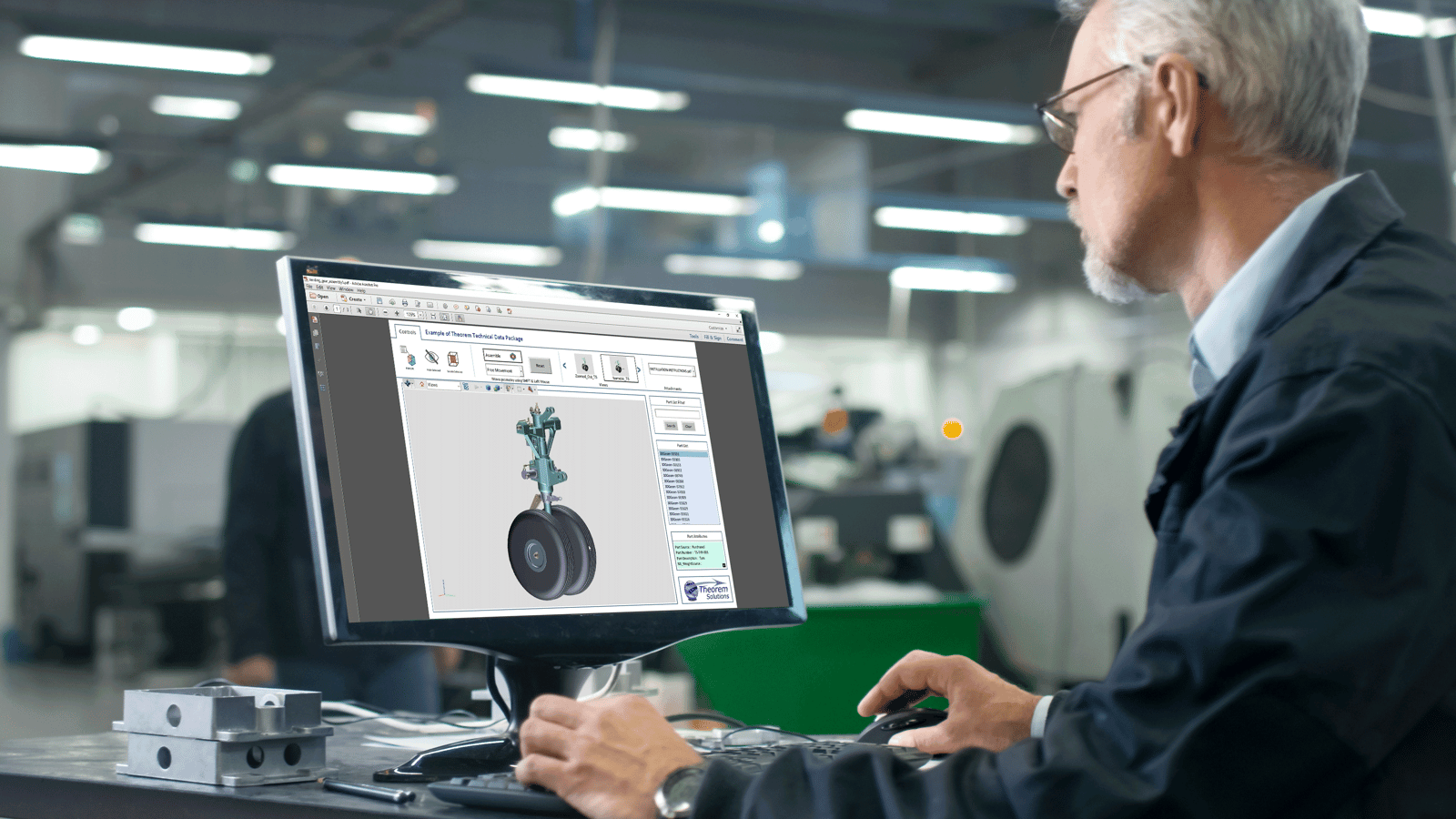

We recently hosted a webinar focusing on the 3D PDF document, and the way it can help companies take the first step to digital transformation. Simply put, a 3D PDF is a lightweight (emailable) and interactive PDF file containing a representation of 3D CAD data.

Watch the full webinar on 3D PDF - The Easy First Step Towards Digital Transformation.

Key takeaways

Here are the 5 key takeaways that we took from this webinar:

1. Companies are taking one step forward and two steps back

2. A way of improving communication and reducing ambiguity

3. Sharing 3D data makes it easier to identify gaps

4. You don’t need to eliminate 2D drawings entirely

5. Your Intellectual Property (IP) is still protected

1. Companies are taking one step forward and two steps back

Many organisations tend to go forward with their 3D CAD packages, possibly integrated with their vault systems or PLM. They will create their designs using 3D CAD, then they will resort back to using their traditional 2D methods of communication.

“We’re looking at an alternative to taking your designed 3D CAD, and then exporting that as a 2D document, be that via emailed PDF or even in some cases, printing it”.

The intention with 3D PDF is to promote using 3D CAD all the way through your design and manufacturing processes rather than using printed 2D drawings. By moving towards a PDF on a screen or tablet and using that for communication instead, this also creates a paperless way of communicating your engineering data.

2. A way of improving communication and reducing ambiguity

By embedding your CAD data and 3D images then sharing that within a PDF, you can remove any ambiguity and improve transparency.

“When you make a quotation, embedding the 3D image of what you’re quoting to supply removes any ambiguity. And with a marking material, instead of having a flat image, why not have an image that the potential customer or client can rotate to fully examine and explore”

3D PDF’s can be used for all sorts of engineering documentation, but another benefit is the ability to leave an audit trail to help improve revision control whilst unlocking a simplified form of communication.

“With change requests and design review documents, you can use the 3D PDF document for the iterations backwards and forwards with a vendor or a supplier by adding notes, requesting changes, or even just asking questions. And then it tracks all those changes, and you’ll know you’re working with the latest document”.

3. Sharing 3D data makes it easier to identify gaps

The interactive functionalities within 3D PDF documents unlock more efficient ways of viewing 3D models and designs, with manipulation tools such as rotate, pan, zoom and taking views or captures from the CAD data.

“When you look here at your standard 2D drawing, and then you look at a rich 3D PDF document, it suddenly makes it a lot easier to see where things are missing. Where there is a gap where shouldn’t be a gap, or where there is a clash where you’ve got parts missing, and even the smaller components that you just don’t see that easily on a 2D document”.

With the ability to display product management information (PMI) and turn it on or off, this replaces the need for multiple 2D drawings. Users can view full assembly tree structures, select and highlight individual parts or components and even select the ‘explode’ option to move components away from each other to get a closer look at the data.

4. You don't need to eliminate 2D drawings entirely

As the usage of 3D data within manufacturing continues to evolve, many companies are still heavily reliant on 2D information, which continues to play a vital role in their engineering processes.

This is where the PDF format comes in handy. Alongside the ability to include 3D CAD data, users can add additional 2D information such as 2D drawings.

“This 3D PDF document also consists of 3 pages – two of them containing 2D drawing sheet information, so if you do need to include 2D information, it can be added as a single package”.

The ability to combine both types of data within a single package smoothens the transition for those that are used to working with 2D drawings, and for those that have already moved towards 3D drawings. Using 3D PDF’s, you can build your very own technical data package, attached with all kinds of information such as CAD data, office documents and images.

“Here we can see the dropdown which lists the attachments – this one showing a spreadsheet containing all the supplier information, and another one for assembly instructions”.

5. Your Intellectual Property (IP) is still protected

3D PDF’s can be shared with anyone, from your close colleagues to those in other countries. With 3D PDF’s, you are only sharing 3D representations of your data, and there are various ways that you can protect your IP, including documents rights management.

“We have two levels of security – the first is the Documents Rights Management, including features such as editing passwords, printing restrictions, commenting controls and form filling controls.”

This can also be catered to enterprise use cases, to protect sensitive information from unauthorised access or usage.

"The second level is Enterprise Information Rights Management, and they include things like web based remote user authenticated document access, encryption, tracking and reporting, watermarking, etc.”

Summary

The 3D PDF is a format that should be used by all companies, regardless of their size who design with mechanical CAD. It promotes a practical and easy way of communicating 3D data across your organisation and your wider supply chain, whilst eliminating the need for reverting from 3D CAD back to 2D drawings, moving organisations towards a paperless and digital environment.

To find out more about 3D PDF, visit our Publish to 3D PDF page or browse our Sample 3D PDF documents to try one out for yourself.