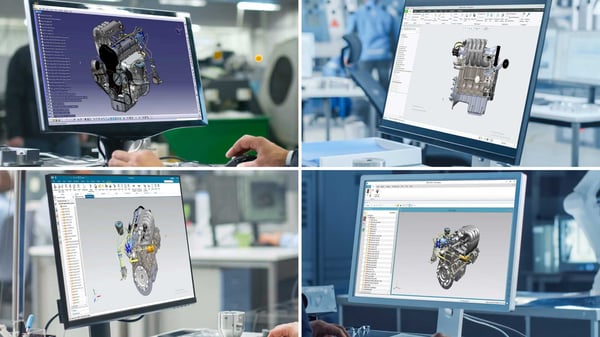

In engineering and manufacturing, sharing CAD design data is a crucial aspect of collaboration between companies. However, challenges arise when partners use different CAD systems, making data translation necessary. To streamline the process, it’s important to follow best practices for CAD data exchange and leverage tools like Theorem's CAD translation products, which offer proven benefits across industries.

Best Practices for CAD Data Exchange

-

Choosing the Right Data Format

Companies typically choose between converting data into neutral formats (such as STEP, IGES, and JT) or direct CAD-to-CAD translations. Neutral formats provide broad compatibility, being widely supported by most CAD software – making them especially useful when working in supply chains with multiple CAD systems. Direct format conversions translate data directly into another CAD format. This method may offer more precision, while preserving detailed design elements.

-

Creating Effective Translation Processes

Establishing standardized procedures is key to minimizing errors. A good first step is to establish clear naming conventions, helping you identify and track each version of the design. Having well-documented steps for exporting, importing translated data is also important. This could include choosing what tools are going to be used for the translation, specifying how the data will be prepared (e.g. removing unnecessary layers or features), and deciding how it will be verified after translation. This ensures everyone involved follows consistent processes, reducing the chance of miscommunication or mistakes.

-

Translating Only Necessary Data

While it may be easier to just translate all of your data, it’s best to only convert the data required to avoid larger file sizes and potential translation errors. Receiving data can make things more difficult since you may not have control over the data you've received. But there are still things you can do; unnecessary layers can be removed from the model along with details regarding components that aren’t relevant to your work. This all improves efficiency and accuracy, ensuring you aren’t bogged down with irrelevant information.

-

Ensuring Data Accuracy

After translation, always verify the data. Even if the software reports no errors, subtle discrepancies (like misaligned geometries or missing components) may still exist. Make sure to check and ensure that the translated data matches the original design, to avoid costly production errors. This could be running a geometry comparison between the original and translated models or checking critical dimensions and tolerances to make sure nothing has been altered.

-

Automating for Efficiency

You can mostly likely translate a few files yourself quite easily but manually translating large volumes of CAD files can be time-consuming. Batch processing and automation tools, like those offered in Theorem's CAD Translate solution, allow users to translate multiple files automatically, reducing manual effort and speeding up the workflow. You can also schedule data to be processed during non-working hours and create a far more efficient process.

How Theorem Can Help

Theorem’s CAD translation products are designed to address the challenges of data exchange, offering reliable, efficient, and accurate tools for companies across industries. Here’s how Theorem can help:

Support for Multiple Formats

Theorem supports translation between a wide range of proprietary CAD systems (e.g., CATIA, NX, Creo, SolidWorks) as well as neutral formats like STEP, IGES, and JT, ensuring seamless collaboration between teams using different software.

Batch Processing for Large Data

Theorem's tools allow for automated translation of large volumes of CAD data through batch processing. This saves time by reducing manual input, plus even more time can be saved by automating translations to be run overnight.

Selective Data Translation

Users can choose to translate only the necessary parts of a CAD model, such as specific components or surfaces, resulting in smaller file sizes as well as optimizing the process by ensuring you are not wasting time converting data that won’t be used.

Seamless PLM Integration

Theorem's solutions integrate with commonly used Product Lifecycle Management (PLM) systems like Siemens Teamcenter and PTC Windchill, automating synchronization and keeping design data consistent across platforms.

Conclusion

CAD data exchange is a critical part of modern engineering and manufacturing workflows, and best practices – such as using the right formats, automating processes, and ensuring data accuracy – are essential to successful collaboration. With proven tools from Theorem's solutions, companies can streamline their CAD translation processes, increase efficiency, and ensure data integrity across projects.

To learn more about how Theorem's solutions can improve your CAD data exchange processes, explore our CADTranslate products or get in touch with our team of CAD specialists today. You can also follow Theorem on LinkedIn for the latest news and insights.